High torque retarder electromagnetic brake

Product Description

Electromagnetic Brake Brief introduction(Dry Single-plate Solenoid Brake)

High quality electro brake motor (also called electro-mechanical brakes or EM brakes) slow or stop motion using electromagnetic force to apply mechanical resistance (friction).

The original name was "electro-mechanical brakes" but over the years the name changed to "electro brake motor", referring to their actuation method. Since becoming popular in the mid-20th century especially in trains and trolleys, the variety of applications and brake designs has increased dramatically, but the basic operation remains the same.

Both electro brake motor and eddy current brakes use electromagnetic force but electro brake motor ultimately depend on friction and eddy current brakes use magnetic force directly.

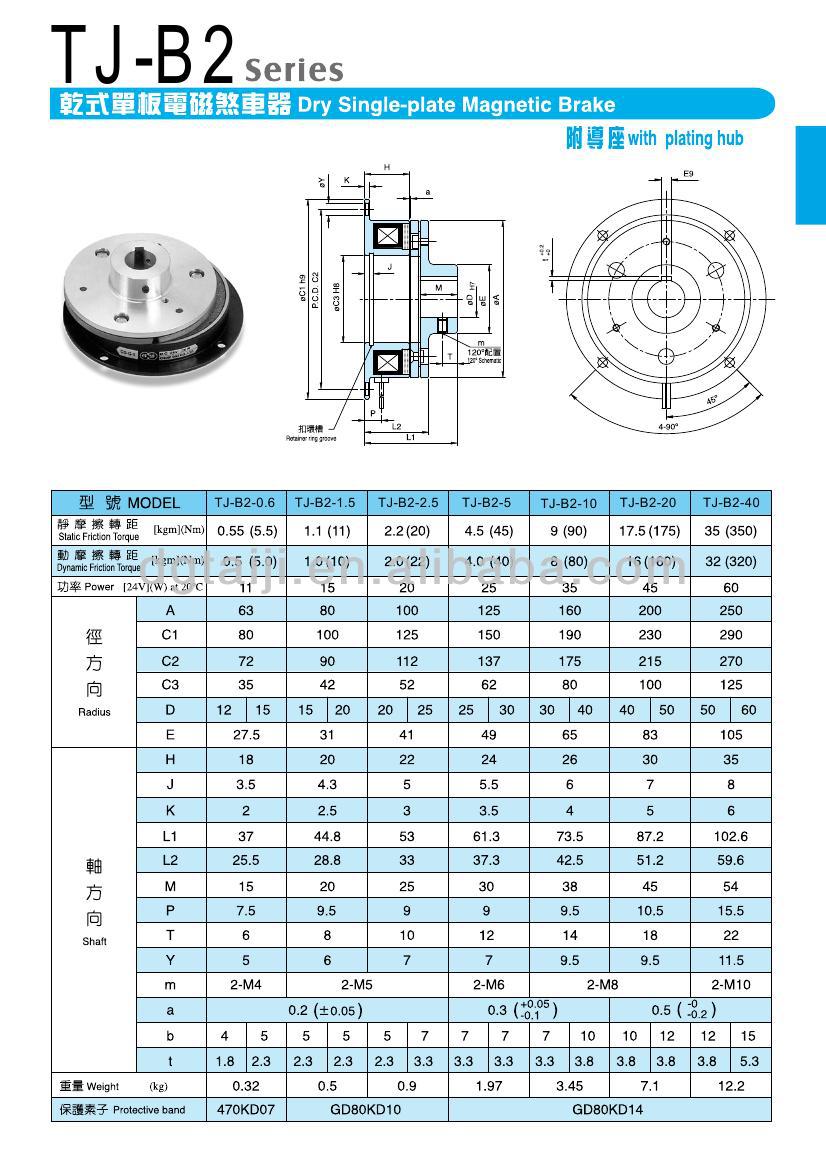

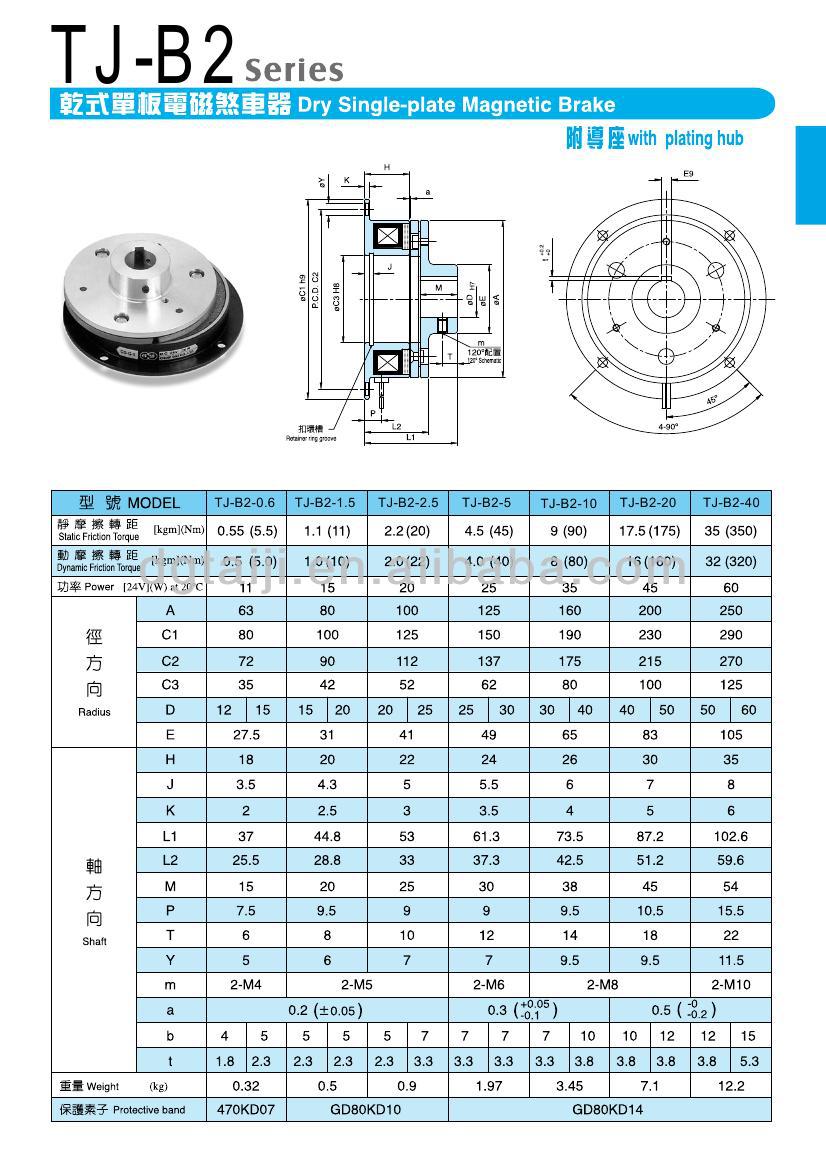

Parameter |

| MODEL | TJ-B2-0.6 | TJ-B2-1.5 | TJ-B2-2.5 | TJ-B2-5 | TJ-B2-10 | TJ-B2-20 | TJ-B2-40 |

| Static Friction Torque(Nm) | 5.5 | 11 | 22 | 45 | 90 | 175 | 350 |

| Dynamic Friction Torque(Nm) | 5 | 10 | 20 | 40 | 80 | 160 | 320 |

| Power (W) 24V at 20°C | 11 | 15 | 20 | 25 | 35 | 45 | 60 |

| Weight (kg) | 0.32 | 0.5 | 0.9 | 1.97 | 3.45 | 7.1 | 12.2 |

|

Electromagnetic Brake Detial

Special features 1. Fast response. Dry design means instant reaction to commands. 2. Durability. Excellent heat dissipation and quality materials mean long life, even under high frequency and high performance conditions. 3. Easy to install and maintain. Sealed bearing race eliminates the need for removal of the center core. No dust brush is needed, and operation is simper and easier. 4. No adjustment of the motor. The motor is designed so that it does not need adjustment of the friction surface, and once it is installed only very minor adjustments are needed. 5. Sure motion. One-piece plate will not slip even under the strongest vibration for longer life. 6. Adjustable torque. Torque levels can be increased or decreased by changing the current, making it suitable for a variety of applications. |

Clik me♦

TJ-B | TJ-B1 |

|  |

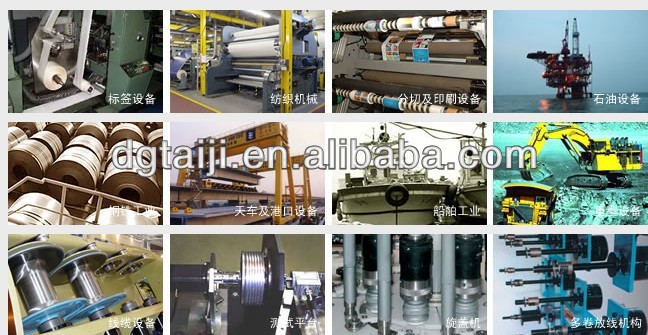

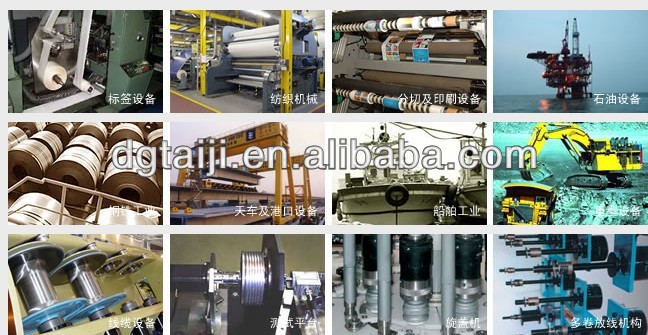

Electromagnetic Brake Appliation

Main application 1. Packing and wrapping system: packing machines, strapping machines, wrapping machinery. 2. Textile machinery: fiber twisters, treatment machines, weaving machines. 3. Metal finishing systems: extruders, wire stretchers, presses, welders, steel wire reactors, cutters, pipe makers, wire winding machines 4. Machine tool systems: laths, millers, steel extruders, CNC lathes, specialized machinery. 5. Transportation equipment: hoists, feeders, conveyors, rollers, winders. 6. Paper-making systems: bad-making machines, box-making machines, slitters, book-making machinery, cutters, copy paper machines. Usage: Connection,disconnection,speed variation, eversible transmission ,positioning slight movement, overload protection etc. |

Packaging & Shipping

Our Services

Why choose us?

Your choice,we promise.

Five Core strengths

1,The first domestic independent R & D manufacturer and 13 years of professional manufacturing. Processing all adopt Taichung precision machine, CNC machine tool production,"Japan's brothers" machining center. Ensuring that the concentricity is less than 0.01 mm.

2,Casting exquisite, beautiful, practical and durable. The lids adopts aluminum die casting, the surface is smooth, precision, anti-seismic. And the hardness is strong.

3,Complete specifications, cost-effective and spot supply.

4,Independent research and development, special specifications can be customized.

5,Selected materials, high-tech treatment, up to the international standard test.

Company Information

Our factory

Our Fairs

Our Dear Partners

Our Market

♣ More concerned for our products , please do not hesitate to inquiry now!

See larger image

See larger image Leave Messages

Leave Messages